Product Center

Contact Us

Email:

cfyxrubberroller@duwogs.com

Phone:

0318-8637001

Address:

No. 369, Fuyang East Road, Jizhou District, Hengshui City, Hebei Province

Rubber Roller Products

This roller is the primary component responsible for maintaining proper tension during film winding. Typically, the film tension is detected by pressure sensors positioned beneath the bearings at both ends of the tension roller. The signals from these sensors are then processed via electronic circuits, which adjust the rotational speed of the winding motor to ensure optimal winding tension.

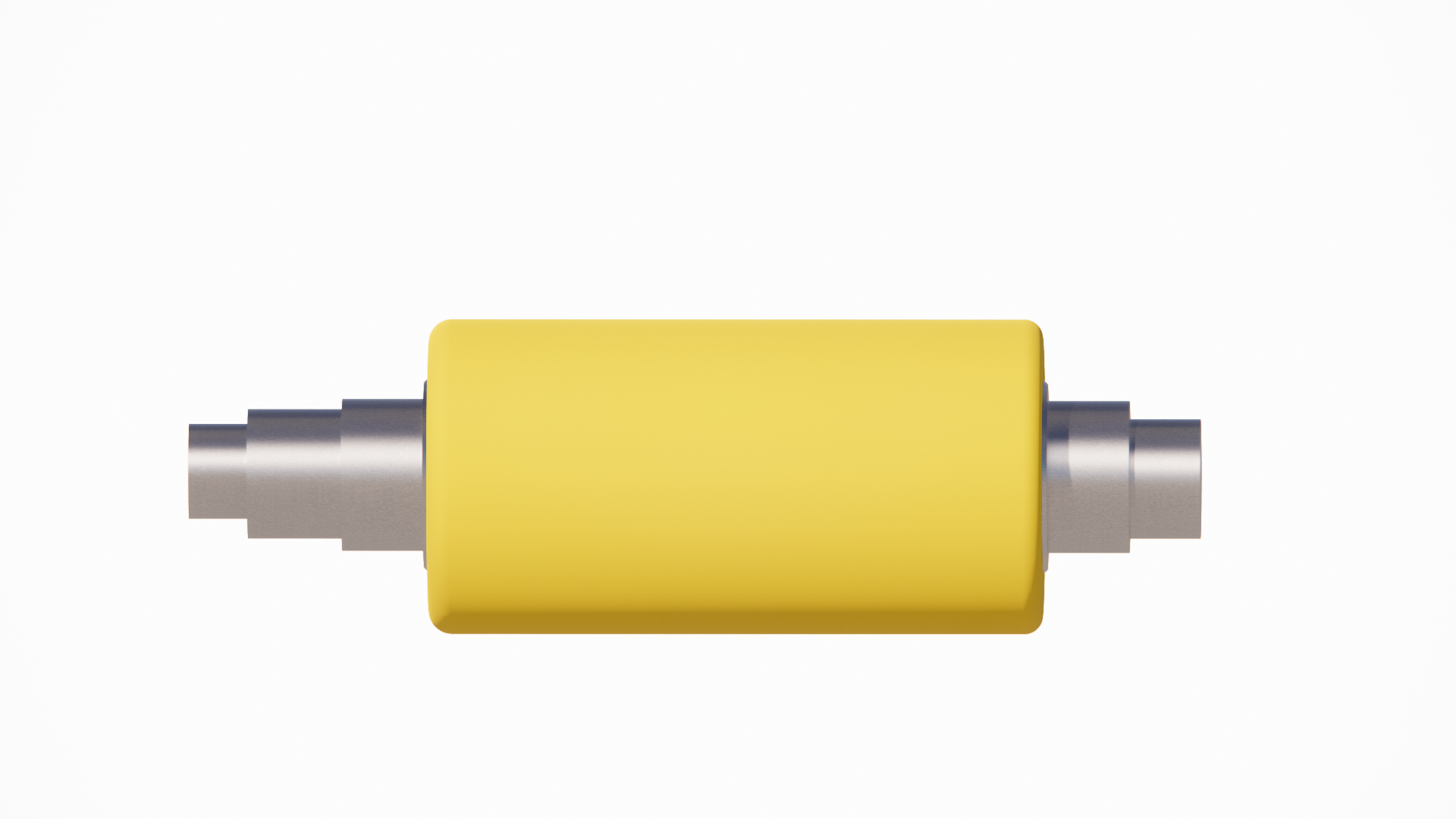

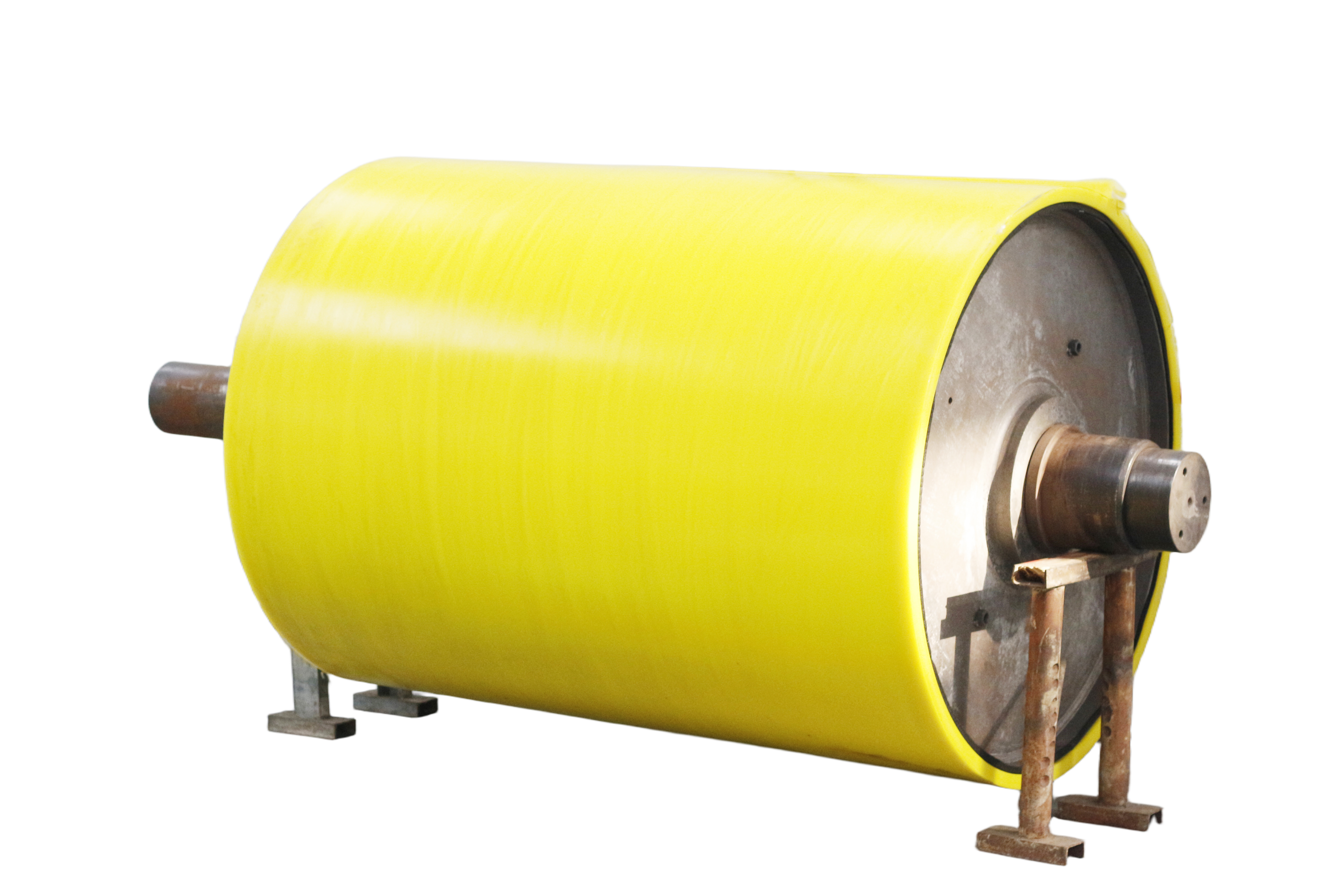

The embossing roller is a specialized roller-type equipment used in industrial production to press raised and recessed patterns onto the surfaces of materials such as plastic sheets, films, aluminum foil, leather, rigid boards, wallpaper, floor tiles, and glass. It is widely applied in industries including papermaking, plastics, rubber, non-woven fabrics, and architectural hardware.

The traction roller is positioned beneath the cooling roller and is primarily used to pull and stretch the plastic film, ensuring it maintains a consistent stretching ratio during the cooling process.

The flattening roller is an industrial equipment component primarily used to address uneven issues such as waviness, wrinkles, and bending that occur in roll materials like films, paper, and metal foils during the production process.

In film casting equipment, the corona roller serves to perform corona treatment, thereby enhancing the surface energy and adhesion of the film.

This roller is the primary component responsible for maintaining proper tension during film winding. Typically, the film tension is detected by pressure sensors positioned beneath the bearings at both ends of the tension roller. The signals from these sensors are then processed via electronic circuits, which adjust the rotational speed of the winding motor to ensure optimal winding tension.

The embossing roller is a specialized roller-type equipment used in industrial production to press raised and recessed patterns onto the surfaces of materials such as plastic sheets, films, aluminum foil, leather, rigid boards, wallpaper, floor tiles, and glass. It is widely applied in industries including papermaking, plastics, rubber, non-woven fabrics, and architectural hardware.

The traction roller is positioned below the cooling roller and is primarily used to pull and stretch the plastic film, ensuring it maintains a consistent stretching ratio during the cooling process.

This roller is the primary component responsible for maintaining proper tension during film winding. Typically, the tension of the film is detected by pressure sensors positioned beneath the bearings at both ends of the tension roller. The signals from these sensors are then processed through electronic circuits, which adjust the rotational speed of the winding motor to ensure optimal winding tension.

The embossing roller is a specialized roller-type equipment used in industrial production to press raised and recessed patterns onto the surfaces of materials such as plastic sheets, films, aluminum foil, leather, rigid boards, wallpaper, floor tiles, and glass. It is widely applied in industries including papermaking, plastics, rubber, non-woven fabrics, and architectural hardware.

The traction roller is positioned beneath the cooling roller and is primarily used to pull and stretch the plastic film, ensuring it maintains a consistent stretching ratio during the cooling process.

The flattening roller is an industrial equipment component primarily used to address uneven issues such as waviness, wrinkles, and bending that occur in roll materials like films, paper, and metal foils during the production process.

In film casting equipment, the corona roller serves to perform corona treatment, thereby enhancing the surface energy and adhesion of the film.

Excellent raw materials and craftsmanship give the product good wear resistance, corrosion resistance, high temperature resistance and other properties, enabling it to adapt to various environments in strip production.

In the production and processing of aluminum sheets and foils, rollers are an important component, mainly used in conveying, laminating, and coating processes.

Roll for base material processing

In the production and processing of aluminum sheets and foils, rollers are an important component, mainly used in conveying, laminating, and coating processes.

Water rollers are rubber rollers in a water supply system that play a vital role in the printing process.

The ink roller is a key component in the printing ink supply system, its main function is to deliver a precise and even amount of printing ink to the printing plate.

Excellent raw materials and craftsmanship enable the product to possess good wear resistance, corrosion resistance, high temperature resistance, and various other properties, capable of adapting to various environments in strip production.

Excellent raw materials and craftsmanship give the product good wear resistance, corrosion resistance, high temperature resistance and other properties, enabling it to adapt to various environments in strip production.

Correcting and feeding rollers

Excellent raw materials and craftsmanship enable the product to possess good wear resistance, corrosion resistance, high-temperature resistance, and various other properties, capable of adapting to diverse environments in strip production.

Excellent raw materials and craftsmanship provide the product with various properties such as good wear resistance, corrosion resistance, and high-temperature resistance, allowing it to adapt to various environments in strip production.

The main function of a UV roller is to transfer and apply UV ink, ensuring that the ink adheres evenly and consistently to the printing material while maintaining good ink transfer performance.