Share to

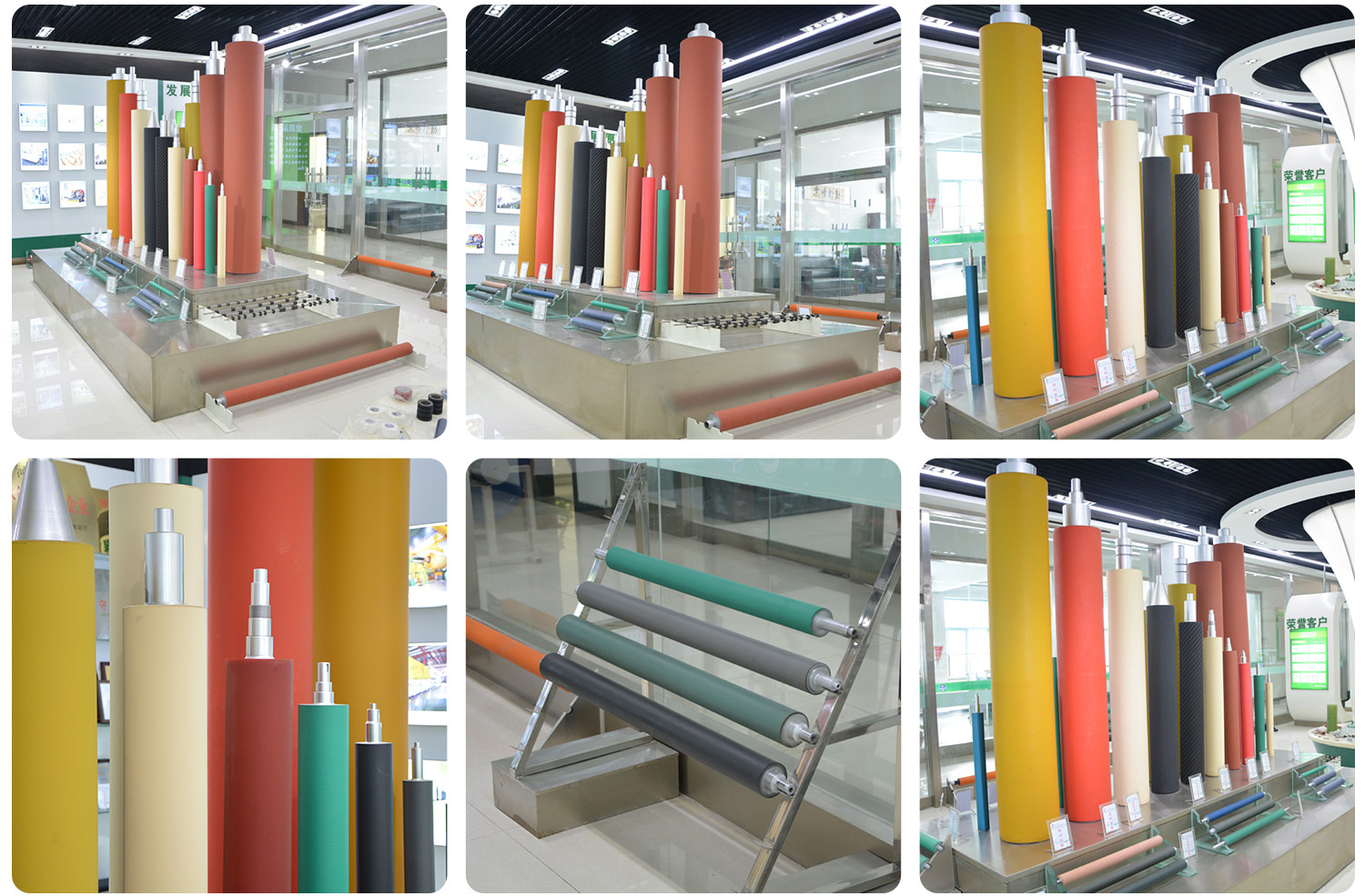

Water roller

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Introduction

Water rollers are rubber rollers in the water supply system that play a crucial role in the printing process. They are similar to ink rollers but serve a different purpose. The main functions of a water roller are:

① To moisten the printing plate, ensuring it maintains the proper level of moisture during printing.

② To regulate the amount of water, preventing ink from spreading on the non-image areas of the printing plate and ensuring the clarity of the printed matter.

③ To protect the printing plate. Evenly moistening the plate helps prevent damage from drying during printing, extending its lifespan.

1. Water Roller with Oscillation: The water roller oscillates back and forth to supply water.

2. Plate-Contact Water Roller: Evenly applies water to the printing plate,

Through appropriate pressure and friction, ensuring that moisture is evenly and stably delivered to the printing plate, providing a strong guarantee for high-quality printed matter.Yin Xing Product Advantages

1. Materials

1) We conduct strict quality checks on all raw materials upon arrival. The quality of raw materials is the cornerstone of the final quality of rubber products.

2) We also strictly control the selection of raw materials, and only materials that pass a series of tests, including small-scale, medium-scale, large-scale trials, and finished product trials, are used.

2. Processes

1) Our equipment is the most advanced processing equipment.

The mixing equipment is advanced auxiliary equipment with an automatic weighing system, reducing human error. The vulcanization process uses advanced intelligent temperature-controlled vulcanization tanks, ensuring stable time, temperature, and pressure during vulcanization. The machining equipment is also the latest Shanghai machine tool, with high processing precision and improved surface cleanliness of the rubber rollers.

2) The mixing process uses a two-stage mixing method, and the molding process uses continuous extrusion and winding molding. The winding molding process has high production efficiency, can meet the needs of large-scale production, has high molding precision, and enhances product competitiveness.

3. Performance Advantages and Impact on Printing Quality

Performance Advantages Impact on Printing Quality High-quality raw materials, polyurethane or other rubber materials are selected according to different requirements. The main materials selected have good elasticity, wear resistance, and corrosion resistance, and can adapt to high-speed printing and high-pressure working environments. Advanced continuous extrusion molding or three-roll rubber-wrapping molding ensures the size and precision of the rollers, improving their strength and durability. Allows the printing rollers to adapt to different printing pressure requirements, ensuring even pressure on the plate during printing. Stable raw materials and continuous and stable production processes ensure the quality of the rollers. Improves printing stability, extends roller lifespan, and reduces costs. Performance Comparison

1. Physical Properties

1) Hardness: Our company's high-quality printing rollers offer a wider range of hardness options, customizable to meet specific customer needs. Standard hardness for printing rollers ranges from 28A to 40A.

2) Elasticity: The printing rollers produced by our company use high-quality materials and advanced manufacturing processes, resulting in excellent elasticity. A decrease in elasticity recovery ability affects the stability of printing results.

Indicators Yin Xing Printing Rollers Ordinary Commercially Available Printing Rollers Rebound Rate ≥40% ≥35% Compression Set ≤5% (70℃×24h, ISO 815B test) 8%-15% (Mid-range models generally >10%) Dynamic Response Speed Recovery within 0.02 seconds (10kHz pressure fluctuation scenario) 0.05-0.1 second recovery (high-speed printing may leave ghosting) 3) Smoothness: Our company controls different smoothness values for different parts of the printing machine, resulting in a fine and even surface. Ordinary rollers have some shortcomings in the uniformity and fineness of smoothness, which will affect the surface quality of the printed matter.

2. Water Transfer Performance

Water Transfer

Uniformity of Water Transfer: Able to transfer water evenly to the printing plate, ensuring that each part of the plate receives the appropriate amount of moisture, thus achieving good printing quality.

Water Absorption: Possesses good water absorption, able to quickly absorb and transfer moisture.

Corrosion Resistance: Has good corrosion resistance, maintaining stable performance during long-term use and reducing water transfer problems caused by corrosion.

Ease of Cleaning: The surface is relatively smooth, not easily adhered to by ink or impurities, and is easy to clean, maintaining good water transfer performance.

Controllability of Water Supply: Able to better control the amount of water supplied, adjusting precisely according to printing needs, helping to achieve ink-water balance.

Water roller

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products