Share to

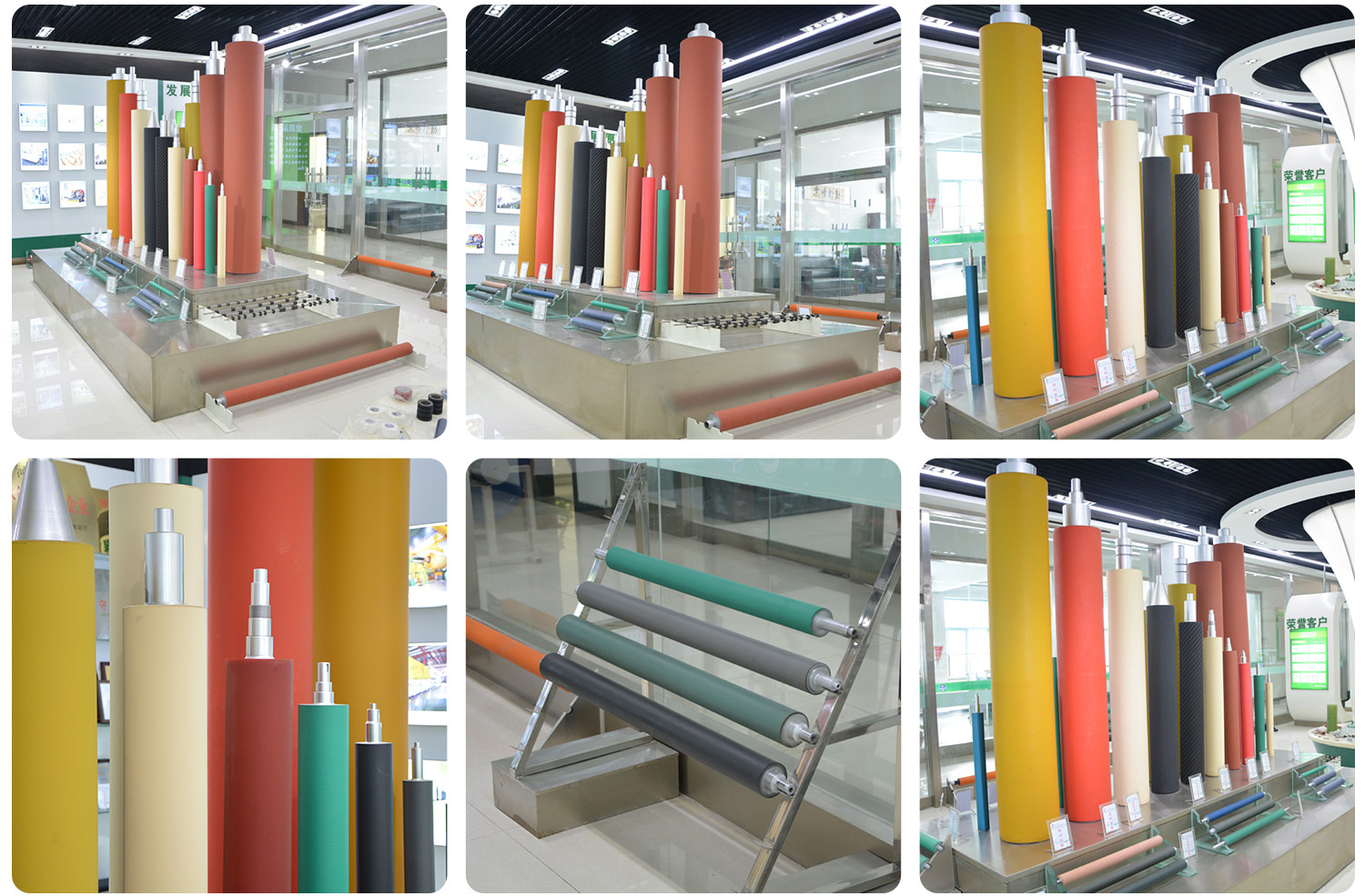

UV roller

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Introduction

The main function of a UV roller is to transfer and apply UV ink, ensuring that the ink adheres evenly and stably to the printing material, especially when enhanced ink adhesion and improved printing quality are required.

The UV roller evenly transfers UV ink onto paper, plastic, or other substrates, forming a glossy protective layer. This not only improves the gloss and water resistance of the printed matter but also enhances its surface wear resistance and scratch resistance.

Because the composition of UV ink differs from ordinary ink, the material of the UV roller must be carefully selected to ensure that it can withstand the penetration of monomers in UV ink while maintaining good ink transfer performance.

UV rollers generally use specific rubber types, such as EPDM, to adapt to the special properties of UV ink and ensure the stability of the printing process and the quality of the printed matter.

Yin Xing Product Advantages

1. Materials

1) We conduct strict quality checks on all raw materials upon arrival. The quality of raw materials is the cornerstone of the final quality of rubber products.

2) We also strictly control the selection of raw materials, and only materials that have passed a series of tests, including small-scale, medium-scale, large-scale trials, and finished product trials, are used.

2. Processes

1) Our equipment is the most advanced processing equipment.

The mixing equipment is advanced auxiliary equipment with an automatic weighing system, reducing human error. The vulcanization process uses advanced intelligent temperature-controlled vulcanization tanks, ensuring stable time, temperature, and pressure during vulcanization. The machining equipment is also the latest Shanghai machine tool, with high processing precision and improved roller surface cleanliness.

2) The mixing process uses a two-stage mixing method, and the molding process uses continuous extrusion winding molding. The winding molding process has high production efficiency, can meet the needs of mass production, has high molding precision, and enhances product competitiveness.

3. Performance Advantages and Impact on Printing Quality

Performance Advantages Impact on Printing Quality High-quality raw materials, polyurethane or other rubber materials are selected according to different requirements. The main material selected has good elasticity, wear resistance, and corrosion resistance, and can withstand high-speed printing and high-pressure working environments. Advanced continuous extrusion molding or three-roll rubber coating molding ensures the size and precision of the roller, improving the roller's strength and durability. Allows the printing roller to adapt to different printing pressure requirements, ensuring uniform force on the plate during printing. Stable raw materials and continuous stable production processes ensure the quality of the rollers. Improves printing stability, extends roller lifespan, and reduces costs.

UV roller

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products