Share to

Textile glue roller

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Product Description

-

Product Introduction

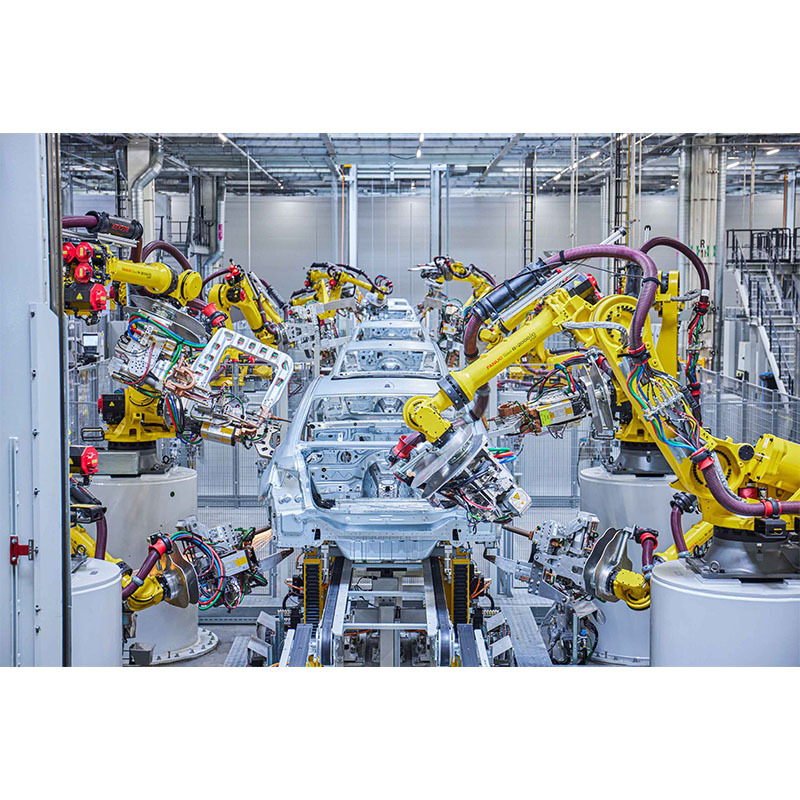

Textile rubber rollers are important components in textile machinery, widely used in spinning, weaving, and dyeing processes. Their main functions are to convey, press, pull, and finish textiles.

Conveying: In textile production lines, rubber rollers are used to convey yarns and fabrics, ensuring smooth operation.

Pressing: In spinning and weaving processes, rubber rollers are used to press fibers or yarns together.

Pulling: Rubber rollers pull yarns or fabrics through frictional force, controlling their tension and speed.

Finishing: In dyeing and post-finishing processes, rubber rollers are used for smoothing, pressing, or coating.

Yin Xing Performance Advantages

Abrasion Resistance: Textile production involves significant friction, requiring rubber rollers with good abrasion resistance.

High-Temperature Resistance: In some processes, rubber rollers need to withstand high temperatures, thus requiring high-temperature resistant rubber materials.

Chemical Corrosion Resistance: In dyeing processes, rubber rollers may come into contact with various chemicals, requiring chemical corrosion resistance.

Surface Smoothness: The surface of the rubber roller must be very smooth to ensure the surface quality of the textiles.

Elasticity: Rubber rollers need to have a certain degree of elasticity to adapt to different thicknesses and materials of textiles.

Application Areas

Spinning: Used in drawing, twisting, and winding processes.

Weaving: Used in weft insertion, beating-up, and winding processes.

Dyeing: Used in dyeing, printing, and finishing processes.

Post-Dyeing Finishing: Used in pressing, coating, and drying processes.

Textile glue roller

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!